With a valuation exceeding $800 billion, the global aerospace sector stands as a fertile ground for innovation. Positioned at the forefront of pioneering manufacturing methodologies and technological advancements, this industry continually pushes the boundaries of possibility. Within this dynamic landscape, aerospace CNC machining emerges as a cornerstone, underpinning critical operations.

Integral to this industry’s essence is an unwavering commitment to safety. Irrespective of the project’s scale or scope, adherence to stringent safety protocols remains paramount. In the aerospace realm, each component must adhere to the most rigorous standards, leaving no margin for error. Whether scrutinizing the minutiae of interior fixtures or the robustness of external structures, any imperfection carries potentially catastrophic consequences.

The exacting standards demanded by aerospace endeavors find an ally in CNC machining. Renowned for its unparalleled precision, this manufacturing process seamlessly aligns with the sector’s exacting requirements. Capable of achieving infinitesimal tolerances for both metallic and composite components, CNC machining epitomizes reliability within aerospace manufacturing. This comprehensive discourse serves as your definitive handbook to aerospace machining and its indispensable role within the industry.

What is Aerospace CNC Machining?

Aerospace CNC machining is a precision manufacturing process tailored for the production of aerospace components utilized in aircraft and spacecraft construction and maintenance. Through advanced computer numerical control (CNC) technology, aerospace CNC machining companies fabricate kits, components, and assemblies crucial for aerospace vehicles.

These components encompass a wide array of parts, such as bushings, hinges, clamps, and bespoke elements, necessitating top-tier materials to ensure optimal performance and safety. Titanium and Kovar emerge as prominent choices due to their exceptional properties suitable for aerospace applications, while supplementary materials encompass aluminum, stainless steel, copper, bronze, and select plastics.

Enhancing Precision in Aerospace Manufacturing

Precision machining stands as a cornerstone within the aerospace industry, embodying the stringent standards and exacting quality control measures that define this sector. Unlike many other domains, aerospace necessitates the utmost precision in every facet of component production, encompassing dimensions, tolerances, and performance parameters.

The imperatives driving this precision are paramount, as any deviation from specifications carries profound consequences. Even a single flawed component has the potential to precipitate substantial financial losses, jeopardizing both aircraft integrity and, more critically, passenger safety. Consequently, aerospace machining enterprises are compelled to uphold uncompromising standards while concurrently adhering to demanding production schedules dictated by market exigencies.

In response to these imperatives, leading manufacturing services such as RapidDirect leverage cutting-edge CNC machining technologies to deliver aerospace prototypes and production-grade components. Working exclusively with aerospace-grade materials, these advanced machining systems boast tolerances as fine as 0.002 mm, ensuring meticulous adherence to design specifications. Complemented by sophisticated post-processing and inspection protocols, these capabilities afford assurance that each aerospace prototype and part meets the exacting standards requisite for aerospace applications.

Utilizing Aerospace CNC Machining: Enhancing Precision and Efficiency

In the realm of aerospace engineering, the utilization of CNC machining stands as a cornerstone for the fabrication of intricate components integral to aircraft construction. The aerospace industry, characterized by its stringent demands for precision, reliability, and weight optimization, relies heavily on advanced manufacturing techniques such as CNC machining to achieve unparalleled levels of quality and performance.

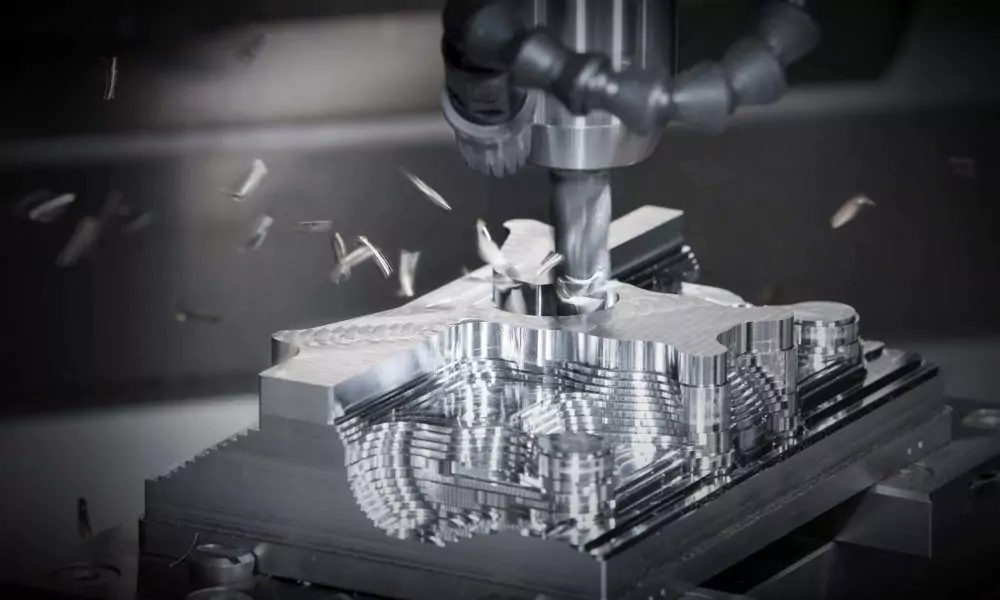

A prime example of CNC machining’s prowess lies in its application of 5-axis machining, enabling the fabrication of highly complex aircraft components with unprecedented efficiency. This cutting-edge process allows for simultaneous milling, drilling, and manipulation along multiple axes, including X, Y, Z, and linear, without necessitating reconfiguration or fixture adjustments. The inherent complexity facilitated by aerospace CNC machining serves as a strategic asset in the quest for weight reduction without compromising structural integrity or functionality.

Aerospace CNC machining enterprises leverage sophisticated design methodologies, workflow software, and state-of-the-art inspection protocols to deliver end-use parts and precision tooling components tailored to the exacting standards of aerospace manufacturers. From hydraulic manifolds to landing gear assemblies, the spectrum of CNC-machined aerospace parts encompasses a diverse array of critical components essential to aircraft functionality.

Beyond its pivotal role in production, CNC machining assumes a crucial position in aerospace research and development endeavors. This pivotal function empowers aerospace entities to expedite the iterative design process, swiftly prototyping, testing, and refining component designs to meet evolving performance criteria. Collaborative ventures between aerospace firms and CNC machining specialists, exemplified by entities like RapidDirect, facilitate the rapid production of CNC-machined prototypes and parts with remarkable turnaround times and tolerances as fine as 0.002 mm, thereby accelerating innovation and driving advancements within the aerospace sector.

Utilizing Aerospace CNC Machining in Aviation

In the realm of aviation, precision holds paramount importance across all aspects of aircraft fabrication, spanning from cargo planes and fighter jets to passenger airliners. This imperative for accuracy permeates every facet of aircraft production, leaving no component untouched, whether internal or external. Take, for instance, the aircraft engine, which serves as the lifeline of flight, demanding optimal fuel processing efficiency to sustain airborne operations. Herein lies the significance of CNC machining, facilitating the production of ostensibly minor yet indispensable engine components.

Moreover, a discerning examination of the cockpit underscores the pivotal role of aerospace machining. Within this critical space, interconnected small-scale components coalesce to form intricate navigational systems essential for seamless point-to-point aircraft navigation. Leveraging CNC machining capabilities enables the fabrication of these indispensable aerospace parts with precision and reliability. Furthermore, meticulous refinement and optimization of pivotal elements such as aircraft wings contribute to the assurance of safe and efficacious flight operations.

Utilization of Aerospace CNC Machining in Space Exploration

When contemplating the realm of space exploration, institutions such as NASA and SpaceX are typically at the forefront of one’s thoughts. These entities are renowned for their conscientious approach to conceptualizing and fabricating cutting-edge spacecraft and rockets tailored for diverse missions. Yet, underlying their endeavors lies a pivotal aspect: aerospace CNC machining. This sophisticated manufacturing process plays a fundamental role in crafting components ranging from the minutest intricacies to the structural framework of rockets.

In the context of space travel, the imperative of constructing spacecraft capable of enduring the rigors of outer space cannot be overstated. Precision is paramount, as every component must not only function flawlessly but also contribute to the overall safety and reliability of the spacecraft. This is where the precision engineering facilitated by CNC machining assumes utmost significance, serving as the linchpin for achieving optimal performance and ensuring the well-being of both crew members and the spacecraft itself.

BOYI Aerospace CNC Machining Expertise

At BOYI, we pride ourselves on our unrivaled expertise in aerospace CNC machining. Our dedicated engineers adhere to the most rigorous industry standards, constantly pushing the boundaries of CNC machining excellence. No matter the precision tolerances demanded by your aerospace components, our seasoned professionals possess the requisite knowledge and skill to meet and exceed expectations. With a proven track record of delivering unparalleled precision, we are committed to providing our clients with superior quality.

BOYI CNC Machining Excellence

Where other CNC machining firms may balk at the challenges presented by your aerospace machining needs, BOYI eagerly awaits your inquiry. We stand prepared to collaborate with you on every aspect of your project, ensuring that the final product aligns precisely with your unique specifications. Simply upload your design files today, and let our cutting-edge platform swiftly generate accurate quotes, empowering you with rapid decision-making capabilities.

Aerospace Machining Utilizing 5-Axis CNC Technology

The manufacturing of aerospace components demands a sophisticated approach, necessitating precision and versatility in production processes. In this context, the utilization of 5-axis CNC machining, exemplified by the advanced capabilities of BOYI machinery, emerges as a pivotal solution.

By harnessing the power of 5-axis CNC technology, aerospace parts can be fabricated with unparalleled intricacy and efficiency. This cutting-edge method enables simultaneous movement across multiple axes, facilitating the realization of complex geometries with utmost accuracy.

The adaptability inherent in 5-axis CNC machining aligns seamlessly with the dynamic nature of the aerospace industry, allowing for swift adjustments and refinements as per evolving requirements. Engineers benefit from the capability to craft components to exacting specifications, whether through milling, drilling, or other machining processes, ensuring adherence to the rigorous standards of aircraft manufacturing.

In essence, BOYI’s 5-axis CNC machining solutions stand as a cornerstone in meeting the exacting demands of aerospace engineering, offering unparalleled precision, versatility, and performance.

Materials Utilized in Aerospace CNC Machining Operations

While aerospace manufacturing often evokes images of intricate engine components and expansive wing structures, it’s imperative to recognize the multitude of components that comprise an aircraft. Take, for instance, the Boeing 747, boasting over 6 million individual parts. Yet, not all of these components undergo CNC machining processes.

Nonetheless, within the realm of CNC machining in aerospace applications, a diverse array of materials finds application in the fabrication of critical components.

Utilizing Advanced Materials in Aerospace CNC Machining

In the realm of aerospace engineering, the selection of materials for CNC machining is a critical aspect governed by two paramount factors: strength and weight. While traditional metals like steel exhibit commendable strength, their weightiness renders them suboptimal for many aerospace applications due to heightened fuel consumption and associated costs.

Enter the imperative shift towards lightweight metals, exemplified by the likes of titanium and aluminum alloys, championed by industry leaders like BOYI. Titanium, renowned for its exceptional strength-to-weight ratio, boasting approximately 30% greater strength and 50% lighter mass compared to steel, emerges as a prime candidate for critical aircraft components. Its superior resistance to elevated temperatures and corrosion further solidifies its status as a preferred material.

Complementing titanium, aluminum alloys offer a compelling balance of lightweight properties and cost-effectiveness, albeit with slightly diminished strength in comparison. Nonetheless, their machinability and versatility make them indispensable for a myriad of aerospace applications, spanning from structural components to exterior fittings.

Meanwhile, in the realm of interior components, the utilization of high-performance plastics takes precedence, driven by their unmatched lightweight attributes and adherence to stringent aerospace safety standards. These aerospace-grade polymers, including PEEK, serve as the cornerstone for fabricating an array of interior elements such as wall panels, ductwork, doors, and electrical conduits, seamlessly integrating durability with compliance to fire retardancy regulations.

In essence, the convergence of advanced materials and precision CNC machining techniques under the stewardship of BOYI underscores a pivotal paradigm shift in aerospace manufacturing, where the pursuit of strength, lightweight design, and regulatory compliance converge to propel the industry towards unprecedented heights of efficiency and innovation.

Conclusion

The aerospace sector, renowned for its stringent quality standards, demands precision and excellence in component manufacturing. Given the criticality of aircraft operations, ensuring top-tier part production is imperative. BOYI, equipped with expertise in aerospace CNC machining, stands prepared to meet the industry’s exacting demands with a steadfast commitment to safety and robust risk management practices.

Embark on Your Next Aerospace Endeavor with BOYI Today

FAQS

Q: What distinguishes CNC machining for aerospace parts from other manufacturing processes?

A: CNC machining for aerospace parts stands out for its precision and versatility in shaping advanced materials like titanium and aluminum alloys to meet the stringent requirements of aerospace engineering. It ensures the production of components with exceptional strength-to-weight ratios, vital for enhancing aircraft performance and fuel efficiency.

Q: How do aerospace machining companies ensure compliance with industry regulations and standards?

A: Aerospace machining companies such as BOYI prioritize adherence to rigorous aerospace standards and regulations governing material properties, component durability, and fire safety. They employ advanced manufacturing techniques and utilize aerospace-grade materials to fabricate parts that meet or exceed regulatory requirements.

Q: What role does precision machining play in aerospace manufacturing?

A: Precision machining is indispensable in aerospace manufacturing, facilitating the creation of intricate components with tight tolerances and complex geometries. Aerospace precision machining ensures the reliability and functionality of critical parts, contributing to the overall safety and performance of aircraft systems.

Q: What are the primary materials utilized in aerospace CNC machining?

A: Aerospace CNC machining primarily utilizes lightweight metals such as titanium and aluminum alloys, renowned for their exceptional strength-to-weight ratios and resistance to harsh operating conditions. Additionally, high-performance plastics like PEEK are employed for interior components, offering durability and compliance with fire retardancy regulations.

Q: How does BOYI contribute to advancements in aerospace manufacturing?

A: BOYI, as a leading aerospace machining company, spearheads innovations in CNC machining techniques and materials selection to address the evolving needs of the aerospace industry. Through its expertise in precision machining and commitment to quality, BOYI plays a pivotal role in enhancing the performance, efficiency, and safety of aerospace systems worldwide.