In today’s dynamic and increasingly tailored market landscape, low volume manufacturing emerges as a pivotal strategy fostering adaptability and ingenuity.

This comprehensive examination delves into the essence of low volume production, elucidating its significance, diverse methodologies, and its indispensable role across various sectors.

Exploring Low Volume Manufacturing

Low volume manufacturing epitomizes the process of crafting a limited array of components or products, typically spanning from a handful to several thousand units. This approach proves optimal for crafting small-scale batches, prototypes, and bespoke items, catering precisely to niche market demands.

Diverging from high volume production models that thrive on mass output, low volume manufacturing emphasizes agility and customization over sheer quantity.

Why Low Volume Manufacturing Matters

Customization and Niche Market Targeting

Low volume manufacturing offers the agility to cater to bespoke product requirements and niche markets. By producing smaller batches, manufacturers can tailor products precisely to meet specific customer needs or address unique market segments, mitigating the financial risks associated with mass production.

Cost-Efficiency in Initial Investment and Tooling

Unlike high volume production models, low volume manufacturing entails lower upfront investment in tooling and setup. This cost-effectiveness renders it an attractive option for startups and small enterprises seeking expedited and economical product launches.

Accelerated Market Entry

Low volume production facilitates swift progression from the design phase to market deployment. This accelerated pace is particularly pivotal in industries characterized by dynamic trends and rapid shifts in consumer preferences.

Risk Mitigation in Product Introductions

Launching new products entails inherent uncertainties regarding market acceptance. Low volume manufacturing enables businesses to test the market viability of their offerings with smaller batches, thereby minimizing potential financial repercussions in case of underperformance.

Facilitation of Emerging Technologies and Materials

The advent of cutting-edge technologies such as 3D printing and CNC machining has expanded the horizons of material innovation and design possibilities. Low volume manufacturing methodologies seamlessly integrate with these advancements, fostering experimentation and adoption of novel materials like carbon fiber.

Emphasis on Sustainability and Waste Reduction

Small-scale production inherently aligns with sustainability goals by minimizing material waste. In an era marked by heightened environmental awareness, this aspect of low volume manufacturing assumes paramount importance, reflecting a commitment to eco-conscious practices.

Differentiating High Volume from Low Volume Manufacturing

High volume manufacturing, synonymous with mass production, revolves around the efficient production of large quantities of standardized products. While benefiting from economies of scale, this approach often sacrifices adaptability, hindering quick responses to market fluctuations or bespoke customer requirements.

Determining the Minimum Production Level

Establishing the minimum production level for low volume manufacturing is contingent upon various factors, including industry dynamics, product intricacy, and manufacturing methodologies employed. Generally, low volume production spans from a few units to several thousand, significantly fewer than the vast quantities characteristic of high volume production, which can extend into the millions.

The decision to opt for low volume manufacturing hinges on multifaceted considerations such as product demand, the feasibility of small-scale production, and the imperative for customization or agile market responsiveness.

Unveiling the Key Advantages of Low Volume Manufacturing

Low volume manufacturing stands as a strategic approach offering a plethora of benefits. Delve into the intricacies of these advantages:

1. Cost Efficiency:

Low volume manufacturing drastically reduces initial costs by minimizing the need for expensive tooling and setup. This financial advantage is particularly appealing for startups and enterprises venturing into new markets or introducing innovative products.

2. Design and Production Flexibility:

Methods such as CNC machining and additive manufacturing afford unmatched flexibility in design and production. This adaptability facilitates swift adjustments, empowering businesses to swiftly respond to evolving market dynamics and customer preferences.

3. Accelerated Time-to-Market:

Low volume manufacturing streamlines the journey from concept to market, a crucial aspect in industries where speed is paramount for maintaining competitiveness.

4. Tailored for Customization and Niche Markets:

Tailored for customization and niche markets, low volume production allows for the creation of bespoke products or addressing specific market segments with ease.

5. Inventory Optimization:

By minimizing production quantities, businesses can significantly reduce inventory costs and the space required for storage, optimizing capital allocation.

6. Risk Mitigation:

With smaller production runs, the risk associated with product launches is mitigated, enabling businesses to gauge market reception without committing to large-scale production.

7. Enhanced Quality Control:

Smaller production volumes enable heightened focus on quality control, ensuring each part meets stringent quality standards.

8. Sustainability:

Low volume manufacturing contributes to sustainability by reducing material waste and energy consumption, aligning with environmentally conscious practices.

9. Simplified Supply Chain Management:

Managing supply chains for low volume production is often simpler and more streamlined, leading to increased efficiency and reduced costs.

10. Access to Advanced Technologies:

Low volume manufacturing is closely intertwined with advanced manufacturing technologies like 3D printing and CNC milling, offering capabilities for producing intricate and high-quality parts.

11. Catalyst for Innovation:

Low volume manufacturing fosters innovation by facilitating experimentation and rapid prototyping, empowering businesses to refine and develop innovative products without committing to large-scale production.

Primary Methods of Low Volume Manufacturing

In the realm of low volume manufacturing, a diverse array of methods exists, each offering distinct advantages and applications. Acquiring an understanding of these various production technologies is paramount for selecting the most suitable approach for your manufacturing requirements. Let’s delve into the key types:

Injection Molding

Injection molding stands as a prevalent method for fabricating plastic and metal components, particularly when precision and scalability are paramount. This technique entails injecting molten material into a mold, which solidifies to yield the final part. Renowned for its ability to deliver high-quality plastic components in limited volumes, injection molding strikes a balance between cost-effectiveness and scalability.

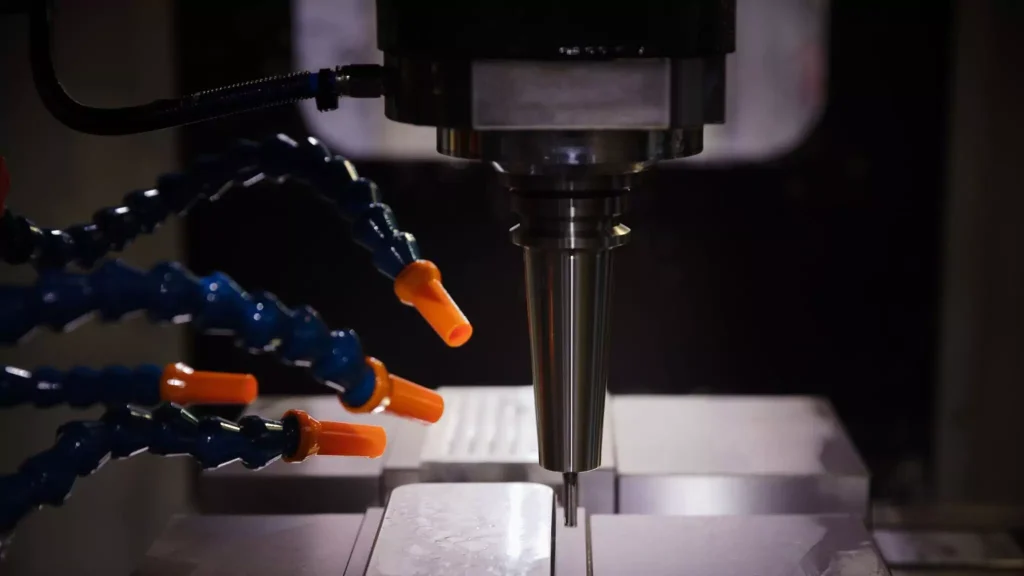

CNC Machining

CNC machining leverages computer-controlled machining tools such as mills, lathes, and grinders to shape materials into desired forms. Esteemed for its precision and versatility, CNC machining excels in crafting intricate parts with stringent tolerances. It serves as a cornerstone in low volume manufacturing, particularly for the production of high-quality steel components or intricate designs.

3D Printing (Additive Manufacturing)

3D printing, also known as additive manufacturing, constructs parts layer by layer from digital designs. This method boasts remarkable versatility, enabling the fabrication of intricate geometries that may be challenging or unattainable with conventional manufacturing techniques. Capable of accommodating a broad spectrum of materials, including plastics, metals, and composites, 3D printing proves invaluable for rapid prototyping and small batch production.

Urethane Casting

Urethane casting employs silicone molds to fabricate parts from various polymers, primarily urethane. This method is invaluable for prototyping and small batch production, offering a cost-effective means to craft high-quality parts with the aesthetics and properties akin to production-grade materials.

Rapid Prototyping

Rapid prototyping integrates various techniques, including 3D printing and CNC machining, to swiftly create scale models of parts or assemblies. This approach plays a pivotal role in modern manufacturing by expediting the design process, facilitating rapid iterations and testing before transitioning to full-scale production.

Sheet Metal Fabrication

Sheet metal fabrication encompasses processes such as cutting, bending, and assembling sheet metal to fabricate diverse metal products. Renowned for its ability to yield sturdy and functional parts, this method is indispensable in industries such as automotive and aerospace.

Vacuum Casting

Vacuum casting involves drawing a liquid material into a mold under vacuum conditions. It excels in replicating parts in small volumes, making it a preferred choice for producing high-quality prototypes or end-use parts.

Laser Cutting and Engraving

Laser cutting and engraving utilize high-powered lasers to precisely cut or engrave materials, commonly metals or plastics. Esteemed for their precision and capacity to generate intricate shapes with impeccable finish quality, these technologies find extensive applications across various industries.

Die Casting

Die casting, often associated with high-volume production, can also be tailored for lower volumes. It entails molding materials under high pressure and is well-suited for crafting metal parts with intricate designs and tight tolerances.

Extrusion

Extrusion involves forcing material through a die to create objects with a fixed cross-section. Widely employed for aluminum or other metals, extrusion is ideal for manufacturing long, straight metal parts.

Understanding Composite Fabrication

Industries that demand robust yet lightweight materials rely on composite fabrication, a process that plays a pivotal role in modern manufacturing.

Composite fabrication entails crafting parts from composite materials, typically a blend of fibers like carbon or fiberglass and a matrix material such as resin. Sectors like aerospace, automotive, and sports equipment leverage this method extensively for its capacity to yield lightweight, exceptionally strong components.

This approach proves invaluable for low volume production parts, enabling the production of specialized components with stringent performance criteria tailored to specific applications or bespoke projects.

Exploring Silicon Molding

Silicon molding emerges as another noteworthy technique in low volume manufacturing, esteemed for its precision and versatility.

Utilizing silicon, renowned for its flexibility, durability, and heat resistance, this method excels in producing parts like gaskets, seals, and other flexible components requiring precise dimensions and shapes.

In industries like medical, automotive, and consumer electronics, where customized or small-batch silicone parts are frequently demanded, silicon molding assumes a pivotal role in fulfilling manufacturing needs.

Key Industries Utilizing Low Volume Manufacturing

Low volume manufacturing isn’t restricted to a single sector; it’s embraced across diverse industries, each capitalizing on its advantages in distinct ways. Here’s an overview of some key industries where low volume manufacturing plays a crucial role:

Aerospace:

Utilizes low volume manufacturing for crafting specialized parts like airframe components and intricate engine parts, emphasizing high-quality materials and precision manufacturing.

Automotive:

Embraces low volume production for custom parts, prototypes, and components for luxury or specialized vehicles, offering design flexibility and rapid adaptation to new technologies.

Medical Devices:

Relies on low volume manufacturing for producing highly specialized medical equipment and devices, where customization and precision are paramount for ensuring safety and efficacy.

Consumer Electronics:

Engages in low volume manufacturing for prototyping new devices and manufacturing high-end, specialized electronics, catering to niche markets or unique customer requirements.

Defense:

Utilizes low volume manufacturing for crafting specialized equipment and components requiring high precision and customization for small, specific applications in defense systems.

Sports Equipment:

Leverages low volume methods to create customized or high-performance gear, such as composite bicycles or specialized athletic wearables tailored to individual preferences and requirements.

Industrial Machinery:

Harnesses low volume manufacturing for producing specialized machinery or parts with precise specifications, addressing niche demands that may not warrant mass production.

Robotics:

Often requires low volume manufacturing for developing unique robotic components that demand customization or are in the developmental stage, facilitating innovation in robotic technologies.

Energy Sector:

Utilizes low volume manufacturing for producing specialized equipment used in power generation, particularly in renewable energy sectors like wind and solar, where custom components are essential for optimizing performance.

Maritime Industry:

Relies on low volume manufacturing for crafting parts in ships and underwater equipment, where the need for custom components is high due to diverse operational environments and unique specifications.

Key Takeaways on Low Volume Manufacturing

In today’s manufacturing landscape, low volume production plays an increasingly vital role, offering advantages such as customization, flexibility, and accelerated time-to-market. When evaluating low volume manufacturing options, it’s essential to carefully consider factors such as cost-effectiveness, time constraints, quality standards, process selection, and supplier partnerships.

Furthermore, the decision between in-house production and contract manufacturing should be based on your specific requirements and capabilities.

BOYI, a leading provider of low volume manufacturing solutions, offers specialized services tailored to your needs, ensuring expert guidance and top-notch outcomes.

As the manufacturing industry continues to evolve, embracing diverse low volume manufacturing approaches can serve as a strategic imperative for businesses aiming to maintain competitiveness and agility in dynamic markets.